Infrastructure

Machinery

Tsudakoma Airjet Looms — 9100 Series

- Ultra-high weaving speeds with stable air pressure control

- Superior uniformity; reduced stops and weaving defects

- Ideal for cotton, blends, Tencel, Modal and sustainable fibers

- Energy-efficient airjet system optimized for mass production

Machinery

Vamatex Leonardo Rapier Looms

- Versatile handling of wide yarn counts and complex blends

- Precise weft insertion for clean color effects and patterns

- Excellent for structured weaves and intricate dobbies

- Premium selvedge formation for fashion and home textiles

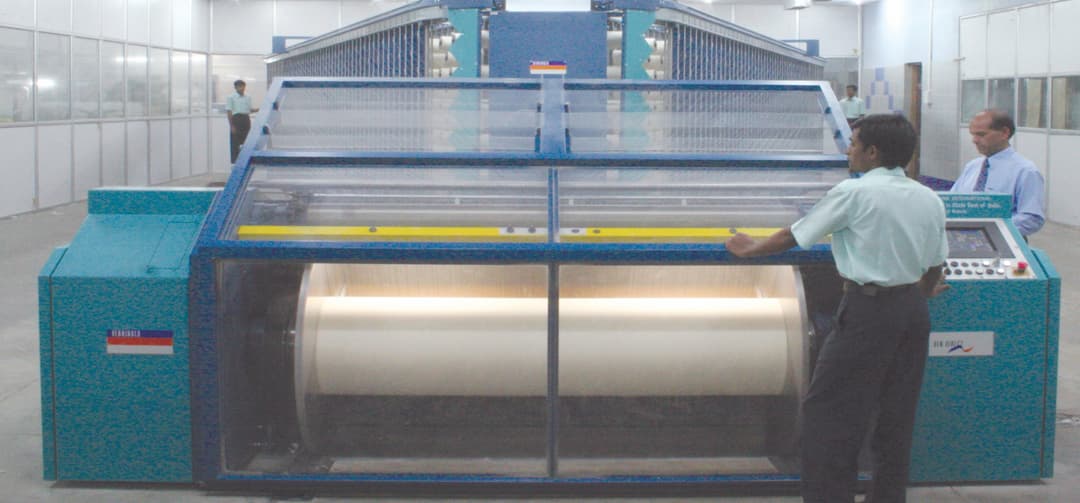

Preparation

Benninger Sizing & Warping

- Consistent sizing film for reduced breakage and higher efficiency

- Optimal warp tension control for airjet and rapier looms

- Advanced moisture & stretch control across beam widths

- Supports sectional & direct/double warping for flexible production

Capabilities

Engineered Fabric Constructions

- Structured weaves, multi-structure dobbies (up to 20 shaft)

- Triple warp, cross-hatch, satin/sateen, broken twill

- Slubs in warp/weft; Seer Sucker & Pleet textures

- Wide blend range: cotton, linen, modal, viscose, Excel, Tencel, bamboo, hemp & more

Leno Expertise

Automatic Leno Weaving with Multi-Dobby

Produced on automatic looms with multi-dobby options for strength, stability, and controlled open-structures. Available variants:

- J-Leno and D-Leno constructions

- Ideal for industrial, functional, and fashion applications

Preparation

Warping & Yarn Preparation

- Sectional warping for fashion stripes & pattern accuracy

- Double/Direct warping for large-scale production

- High-precision tension control; slub & specialty yarn-friendly

100+

Advanced Looms

20

Shaft Dobbies

24/7

Quality Control

Quality & Testing

Precision at Every Stage

- Strict international 4-point inspection for greige & finished fabrics

- Auto-coned yarns; shade-controlled yarn-dyed cotton & blends

- Humidity/temperature-controlled testing environment

- Checks at every stage: Yarn → Warping → Sizing → Weaving → Finishing

R&D & Innovation

Custom Solutions & Development

- Concept-to-fabric development for global fashion & home

- Rapid sampling; moodboards, swatches, and pattern development

- Custom constructions: counts, densities, weaves, finishes

- Private label & brand-specific textures/patterns